When it comes to machine embroidery, choosing the right needle can make all the difference, especially when working with metallic thread. Metallic threads can be a bit temperamental, but with the right needle, you can ensure your designs come out looking stunning. In this blog post, we’ll explore the best needle size for metallic thread and how to get the most out of your machine embroidery projects.

Why Metallic Thread Needs Special Attention

Metallic threads are made with a core of metal or a metallic foil, which can be prone to fraying and breakage. This is why they require specific needles designed to handle their unique properties. Using the wrong needle can lead to thread breaks, needle jams, and poor stitch quality, all of which can be frustrating and time-consuming to fix. Here we can look for some types of threads to be used.

Choosing the Right Needle Size

For machine embroidery with metallic thread, the needle size plays a crucial role. Here’s what you need to know:

- Needle Type: Use a needle specifically designed for metallic threads. These are often referred to as “Metallic” needles or “Specialty” needles. They have a larger eye to accommodate the thicker metallic thread and reduce friction.

- Needle Size: The most common needle sizes recommended for metallic thread are between 75/11 and 90/14. The choice between these sizes depends on the fabric and the thickness of the metallic thread.

- 75/11 Needles: Ideal for lightweight fabrics like silk or polyester. This size works well with finer metallic threads and provides a delicate stitch.

- 90/14 Needles: Better suited for medium to heavy fabrics such as denim or canvas, and thicker metallic threads. It provides more stability and reduces the risk of thread breakage.

- Needle Brand: While needle size and type are important, brand quality can also affect your embroidery results. Brands like Schmetz, Organ, and Janome offer high-quality needles designed for metallic threads. Their specialty needles usually come with features like a larger eye and a special coating to reduce friction.

Additional Tips for Working with Metallic Thread

- Thread Tension: Adjust your machine’s tension settings. Metallic threads often require a looser tension to prevent them from breaking. Start with a slightly lower tension and test on a scrap piece of fabric before starting your main project.

- Stabilizers: Use the right stabilizer for your fabric and thread combination. A tear-away or cut-away stabilizer can help provide support and prevent puckering.

- Needle Changes: Metallic threads can dull needles faster than regular threads. It’s a good idea to change your needle frequently when working with metallic thread to maintain optimal stitch quality.

- Speed: Slow down your machine speed when using metallic thread. Slower stitching reduces the risk of thread breakage and ensures better control.

Conclusion

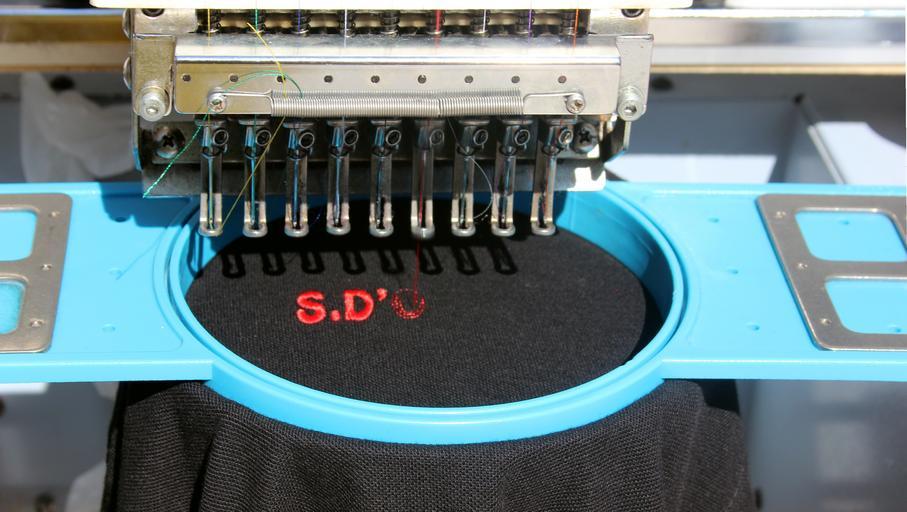

In summary, selecting the right needle size for metallic thread in machine embroidery is essential for achieving professional-looking results. A needle size of 75/11 or 90/14, designed specifically for metallic threads, will help you navigate the challenges of working with these shiny, delicate threads. Along with proper tension adjustments and the right stabilizer, using the appropriate needle will enhance your embroidery experience and ensure your designs shine brightly. Here we can see some Machine Embroidery Designs

Leave a Reply